Laminar Flow

What Is Laminar Flow?

Laminar flow, or laminar air flow (also called streamline flow), is a liquid flow, in which the fluid moves in separate paths, as opposed to turbulent flow, where the fluid undergoes intermixing.

As is clear from the definition, all the flow properties are always persistent in laminar air flow. On a flat level surface, laminar air flow consists of several parallel layers. When contacting with the flat surface, the fluid stays motionless, though all the layers begin to slide over one another.

When a liquid or gas flows evenly and with no turbulence, such a phenomenon can be called a “laminar flow”. A bright example would be the arcing streams in a fountain where a mass of pure water is fired like a bullet and sweepingly slicing through the air from one spot to another.

Applications

It’s applicable to those areas of industrial cleaning where the working environment must be critically clean — for example, in cleanroom technology or in laminar air flow cabinets. In general, quasi-laminar flows with low turbulence are widely used in preparing rooms for surgery, for creating semiconductor technologies and pharmaceutical products.

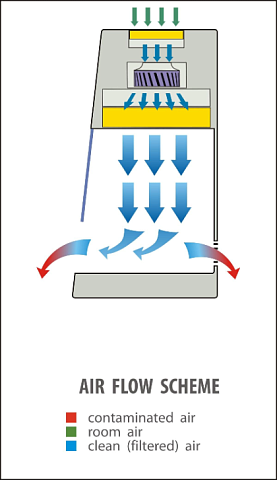

Operating Principle

Laminar flow is possible not only in pipes but in almost any confined space, such as cisterns and pipelines. However, there is an important condition that the surfaces of the nozzles are as smooth as possible. The cleaning process itself begins with the fact that air streams are transported to the working chamber as a vertical unidirectional (laminar) uniform-velocity downflow followed by its displacement back into the environment. The air flow absorbs the contaminations arising during the operation in the working chamber and leaves the chamber into the environment through the front opening and the rear air grille. These outflows prevent the penetration of the external contaminations into the working chamber. So, critical work areas and equipment are less intensively contaminated.