BMB-II-"Laminar-S."-0,9 SAVVY SL Class II Biological Safety Cabinet

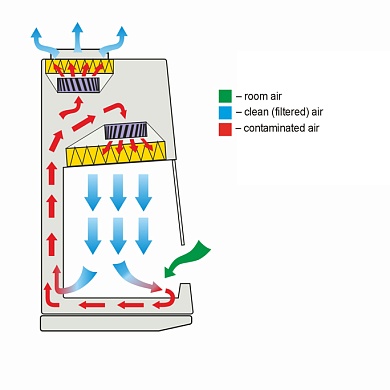

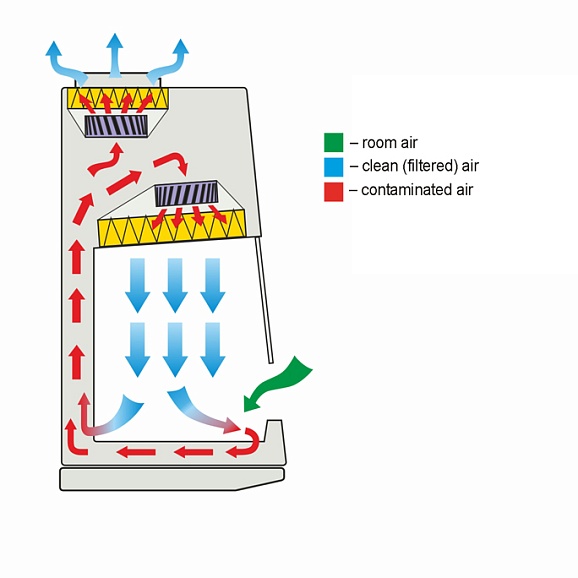

The microbiological safety cabinet Class II SAVVY SL is designed for work with agents of biosafety levels I, II and III. It provides product, operator and environment protection.

Savvy SL is a new generation of the microbiological safety cabinets that inherited all the advantages of the previous models.

KEY BENEFITS

POWER DRIVEN FRONT SASH.

Five specified positions of the front sash:

- Operating position is settled in accordance with EN 12469

- Completely closed position is used in Stand-by Mode

- Down position – for cleaning and disinfection

- Up position – for loading the working chamber

- Stop before closing

FRONT SASH STOP PRIOR TO CLOSING. Automatic stop of the front sash at 40 mm height from the surface prior to complete closing of the front opening prevents any injury of the operator’s hands.

STOP AHEAD OF OBSTACLE. To ensure maximum safety, the moving front sash automatically stops in case of contact with an object or a hand of the operator.

MICROPROCESSOR CONTROL SYSTEM. The cabinet is featured with a microprocessor control system that immediately informs an operator on the reduction of the level of the cabinet protection via alarm messages displayed on the touchscreen and via an audible and visible alert.

The fan motor control system SintelL-1 minimizes the power consumption of the operating cabinet as well as reduces the level of acoustic and electromagnetic noise.

The system of static airflow stabilization AIS LS automatically maintains the air balance in the work chamber increasing the fan rpm as filters get clogged. Upon reaching the clogging threshold, the alarm is activated.

Mode monitoring system featured with audible and visible alarm indicates any disturbance of the air balance in the work chamber.

AUDIBLE AND VISIBLE ALARM SYSTEM. Alarms are automatically activated in case the airflow parameters deviate from the preset values.

LOW LEVEL OF NOISE.

TOUCHSCREEN CONTROL PANEL. It ensures clear visualization of operating modes and simple control of the cabinet as well as provides the user with more service and maintenance information. The screen allows for work in gloves and disinfection with liquids, i.e. hydrogen peroxide.

Additional options

BMB-II-"Laminar-S."-0,9 SAVVY SL Class II Biological Safety Cabinet

The microbiological safety cabinet Class II SAVVY SL is designed for work with agents of biosafety levels I, II and III. It provides product, operator and environment protection.

Savvy SL is a new generation of the microbiological safety cabinets that inherited all the advantages of the previous models.

KEY BENEFITS

POWER DRIVEN FRONT SASH.

Five specified positions of the front sash:

- Operating position is settled in accordance with EN 12469

- Completely closed position is used in Stand-by Mode

- Down position – for cleaning and disinfection

- Up position – for loading the working chamber

- Stop before closing

FRONT SASH STOP PRIOR TO CLOSING. Automatic stop of the front sash at 40 mm height from the surface prior to complete closing of the front opening prevents any injury of the operator’s hands.

STOP AHEAD OF OBSTACLE. To ensure maximum safety, the moving front sash automatically stops in case of contact with an object or a hand of the operator.

MICROPROCESSOR CONTROL SYSTEM. The cabinet is featured with a microprocessor control system that immediately informs an operator on the reduction of the level of the cabinet protection via alarm messages displayed on the touchscreen and via an audible and visible alert.

The fan motor control system SintelL-1 minimizes the power consumption of the operating cabinet as well as reduces the level of acoustic and electromagnetic noise.

The system of static airflow stabilization AIS LS automatically maintains the air balance in the work chamber increasing the fan rpm as filters get clogged. Upon reaching the clogging threshold, the alarm is activated.

Mode monitoring system featured with audible and visible alarm indicates any disturbance of the air balance in the work chamber.

AUDIBLE AND VISIBLE ALARM SYSTEM. Alarms are automatically activated in case the airflow parameters deviate from the preset values.

LOW LEVEL OF NOISE.

TOUCHSCREEN CONTROL PANEL. It ensures clear visualization of operating modes and simple control of the cabinet as well as provides the user with more service and maintenance information. The screen allows for work in gloves and disinfection with liquids, i.e. hydrogen peroxide.

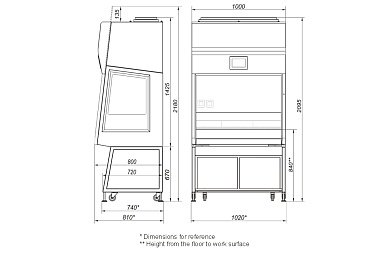

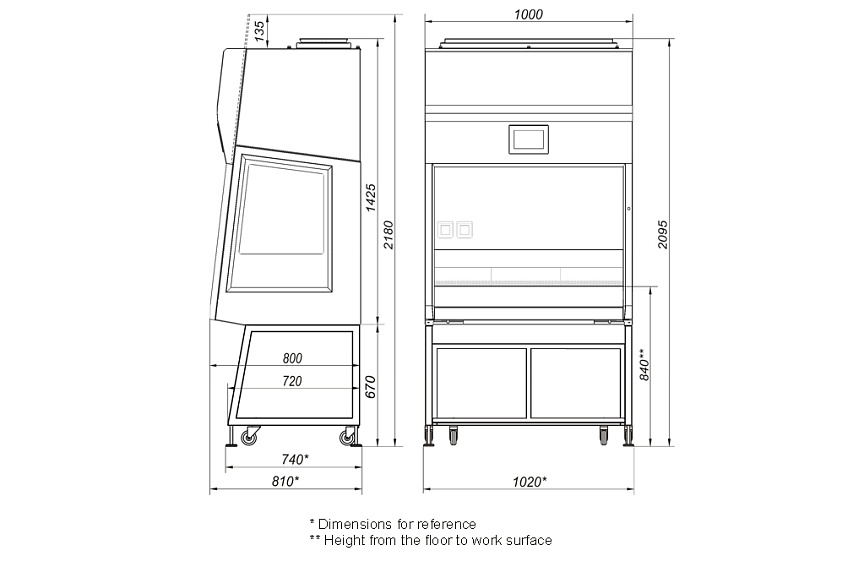

Main parameters and dimensions

Microbiological safety cabinet BMB-II-“Laminar-S.”-0,9 SAVVY SL Class II

| Article | 2E-B.008-09 |

| Dimensions of the cabinet with the stand in assembly (WxDxH), mm | 1000x810x2095 |

| Dimensions of the cabinet with stand and completely opened front sash (WхDхH).mm | 1000х810х2180 |

| Dimensions of the working chamber (WxDxH), mm | 905x610x700 |

| Weight of the cabinet with the stand in assembly (net), kg, not more than | 215 |

| Cabinet's power supply parameters: | |

| - voltage, V~ | 220±10% |

| - frequency, Hz | 50±1 |

| Maximum power consumption (without the built-in outlets load), W, not more than | 680/220* |

| Total acceptable load on the built-in outlets, W, not more than | 1000 |

* The power consumption was measured in the cabinet with newly installed (uncontaminated) HEPA filters.

MAIN CHARACTERISTICS

| Installation work chamber air cleanliness class for suspended particle (aerosol) concentration as per ISO 14644-1 | |

| - for particles of 0.5µm and more | ISO 5 |

| - for particles of 5.0µm and more | ISO M (20; ≥5µm); LSAPC |

| Cabinet class according to ЕN 12469 | II |

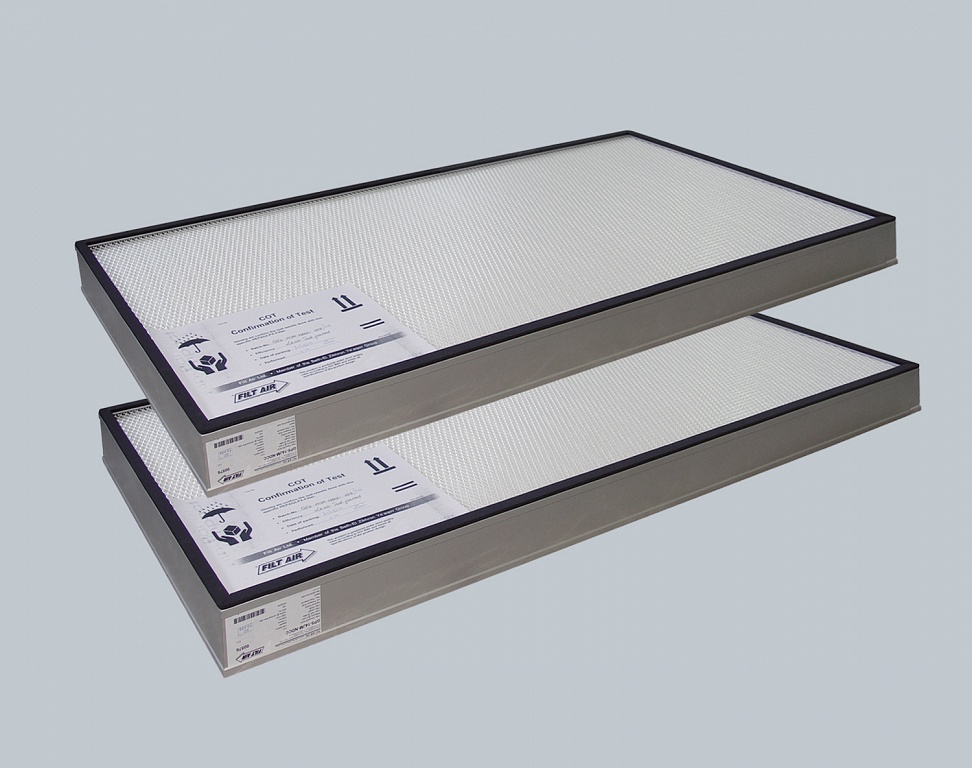

| Class of the installed НЕРА-filters according to EN 1822-1 | H14 |

| Average velocity of the inflow though the work opening, m/s | 0,47±0,03 |

| Average downflow velocity in the working chamber, m/s | 0,35+0,01 |

| Clean air inflow volume, m3/h | 656-674 |

| Air outflow volume, m3/h | 289-328 |

| Air recirculation rate in the cabinet, % | 2000 |

| Air recirculation rate in the cabinet, % | ≈ 70/30 |

* The power consumption was measured in the cabinet with newly installed (uncontaminated) HEPA filters.

Dimensional drawing

Air flow scheme

Standard Configuration

Work Chamber

- front sash made of laminated safety glass;

- side windows made of tempered glass:

- right side window - with tap ports on the right,

- left side window – with pass-through ports;

- slanted front surface of the cabinet;

- adjustable work chamber LED lighting;

- two electric sockets in the work chamber (in the left part of the rear wall);

- airflow laminarization screen made of polymer micromesh;

- three-section tabletop made of stainless steel (AISI 304) with air intake grille in the front;

- work chamber tray made of stainless steel (AISI 304);

- removable armrest made of stainless steel (AISI 304)

Sash Lifting/Lowering

- the front aperture opening and closing is carried out by moving the front sash in the plane of the aperture;

- power drive;

- the sash is hanging on the two flat belts rigidly fixed to the glass;

- there is no counter-weight in the configuration.

UV Unit

- pullout (when inoperative, is stored outside of the work chamber under the tabletop);

- metal grille protecting the UV lamp;

- dampers against any impact upon lowering the work opening screen.

Supply and Exhaust Air Filtration System

- supply air coming into the work chamber is cleaned by supply HEPA filter H14;

- exhaust air coming out of the cabinet is cleaned by exhaust HEPA filter H14;

Control System Components

- microprocessor control system;

- touchscreen control panel;

- airflow sensors*;

- front sash and UV unit position sensors;

- belt tension sensors;

- individual fuse for power supply to the main functions of the cabinet (fan, lighting, UV lamp);

- individual fuse for electric sockets of the work chamber;

- removable power cord;

- dry (voltage-free) output for connecting external devices and transferring the data on the current status of the cabinet.

Testing Components

- built-in outlets for sampling the air upstream of HEPA filters for their integrity testing (located in the right part of the rear wall).

Stand

- frame stand with footrest;

- caster wheels for cabinet relocation;

- screw supports for cabinet fixation at operating site.

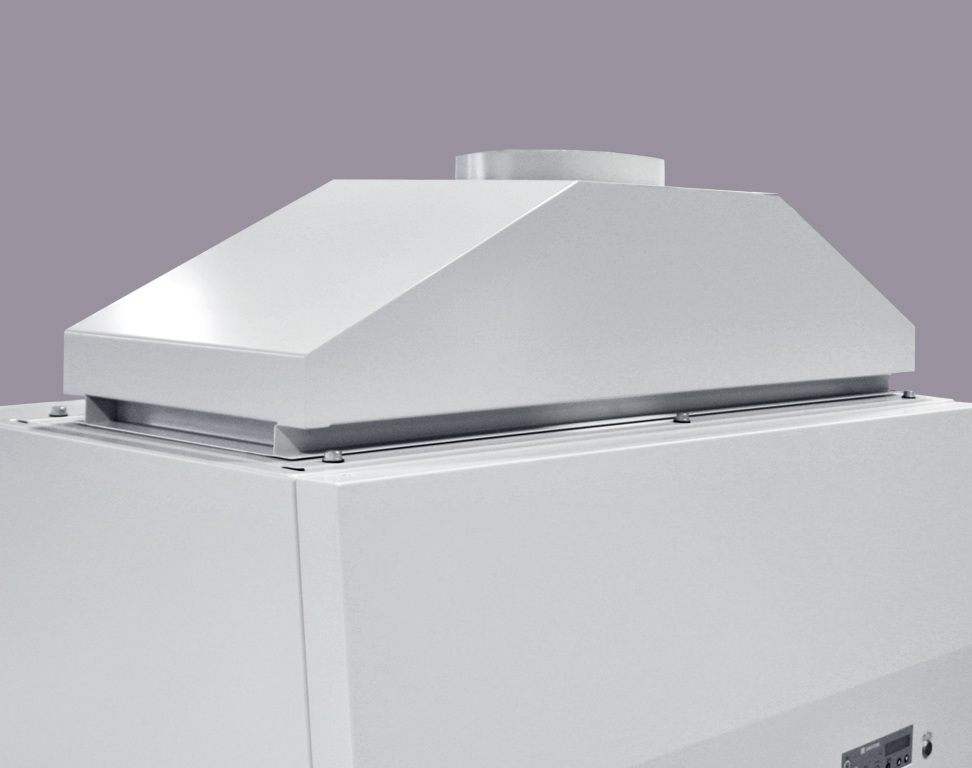

Additional options