BMB-II-"Laminar-S."-1,2 SAVVY SL CYTOS Class II Biological Safety Cabinet

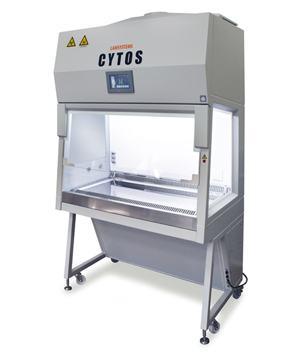

Biological safety cabinet Class 2 Cytos is designed for work with cytostatic and cytotoxic agents.

The cabinet Cytos provides product, operator and environment protection for work with agents of biosafety levels 1, 2 and 3.

Application of the Microbiological Safety Cabinet

- Personnel protection from exposure to antineoplastic (cytostatic and cytotoxic) compounds when working with such;

- Aseptic preparation of the antineoplastic (cytostatic and cytotoxic) products

- Physical isolation (containment and controlled removal from the work zone) of pathogenic biological agents (PBA) and microorganisms to prevent airborne infection of the staff and contamination of the air in the work room and to protect the environment.

-

minimization of risk of contamination and cross-contamination of the product;

- the cabinet is used to equip individual work places in medical, pharmaceutical and other institutions working with pathogenic biological agents and microorganisms;

- the necessity of the cabinet connection to the exhaust system is determined individually by the exploitation organization judging on the analysis and assessment of the risks. In case of the cabinet connection, it must be provided the exhaust ventilation system capacity of 750-1000 m3/h.

- If the cabinet is used for work with pathogenic biological agents (PBA) and high-risk (especially hazardous) microorganisms, a corresponding protective (antiplague) coverall shall be used.

Key Benefits

- Extra measures for operator and environment protection are provided in Cytos cabinet. Four intermediate cylindrical HEPA filters H14 are installed parallel to each other and located under the work chamber worktop. FILTER REPLACEMENT IS PERFORMED WITH WORKING FANS through the work chamber without additional dismantling of the cabinet. Therefore it minimizes the risks of personnel and environment contamination.

- The table top is a quick-removable tray to ease up the collection of spilled materials, the tray under the table top prevents liquid leakage inside the cabinet.

- The system of monitoring the cabinet's operating modes warns the operator about the air flow imbalance in the work chamber with an audible-visible alarm.

- A unique pull out UV-unit is included into the basic configuration.

BMB-II-"Laminar-S."-1,2 SAVVY SL CYTOS Class II Biological Safety Cabinet

Biological safety cabinet Class 2 Cytos is designed for work with cytostatic and cytotoxic agents.

The cabinet Cytos provides product, operator and environment protection for work with agents of biosafety levels 1, 2 and 3.

Application of the Microbiological Safety Cabinet

- Personnel protection from exposure to antineoplastic (cytostatic and cytotoxic) compounds when working with such;

- Aseptic preparation of the antineoplastic (cytostatic and cytotoxic) products

- Physical isolation (containment and controlled removal from the work zone) of pathogenic biological agents (PBA) and microorganisms to prevent airborne infection of the staff and contamination of the air in the work room and to protect the environment.

-

minimization of risk of contamination and cross-contamination of the product;

- the cabinet is used to equip individual work places in medical, pharmaceutical and other institutions working with pathogenic biological agents and microorganisms;

- the necessity of the cabinet connection to the exhaust system is determined individually by the exploitation organization judging on the analysis and assessment of the risks. In case of the cabinet connection, it must be provided the exhaust ventilation system capacity of 750-1000 m3/h.

- If the cabinet is used for work with pathogenic biological agents (PBA) and high-risk (especially hazardous) microorganisms, a corresponding protective (antiplague) coverall shall be used.

Key Benefits

- Extra measures for operator and environment protection are provided in Cytos cabinet. Four intermediate cylindrical HEPA filters H14 are installed parallel to each other and located under the work chamber worktop. FILTER REPLACEMENT IS PERFORMED WITH WORKING FANS through the work chamber without additional dismantling of the cabinet. Therefore it minimizes the risks of personnel and environment contamination.

- The table top is a quick-removable tray to ease up the collection of spilled materials, the tray under the table top prevents liquid leakage inside the cabinet.

- The system of monitoring the cabinet's operating modes warns the operator about the air flow imbalance in the work chamber with an audible-visible alarm.

- A unique pull out UV-unit is included into the basic configuration.

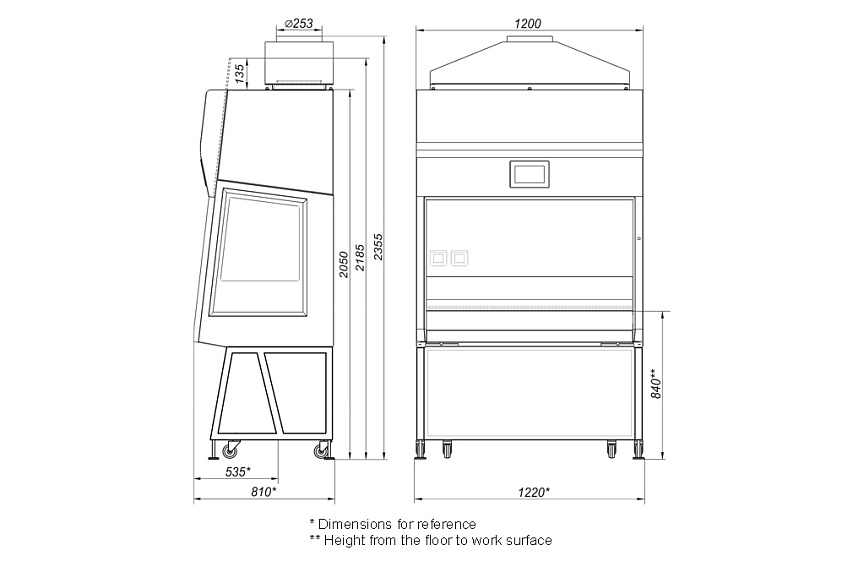

Main parameters and dimensions

Microbiological safety cabinet BMB-II-“Laminar-S.”-1,2

SAVVY SL CYTOS * Class II

*Not for sale in CH DE DK AT NL

| Article | 2E-B.013-12 |

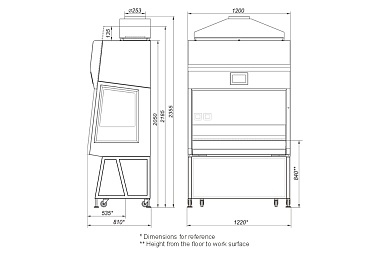

| Dimensions of the cabinet with the stand in assembly without an exhaust hood *(WxDxH), mm | 1200х770х2095 |

| Dimensions of the cabinet with the stand in assembly with an exhaust hood* (WxDxH), mm | 1200х770х2355 |

| Dimensions of the working chamber (WxDxH), mm | 1105x610x660 |

| Weight of the cabinet with the stand in assembly (net), kg, not more than | 270 |

| Power consumption (without the built-in outlets load), W, not more than | 810/140** |

| Total acceptable load on the built-in outlets, W, not more than | 1000 |

| Air volume supplied to the work chamber of the cabinet, m3/h | 795-817 |

| Noise level at 1m distance from the cabinet, dBA, not more than | 58*** |

* dimensions do not account for outstanding supports

** Power consumption with newly installed (uncontaminated) HEPA filters.

*** level of noise measured as per DIN EN ISO 11201 in free sound field over the sound-reflecting surface (noise level in real operating environment depends on the dimensions of the operating site as well as and on the total background noise and may vary by 3-4 dB(A))

MAIN CHARACTERISTICS

| Installation work chamber air cleanliness class for suspended particle (aerosol) concentration as per ISO 14644-1 | |

| -for particles of 0.5µm and more | Class 5 |

| -for particles of 5.0µm and more | ISO M (20; ≥5µm); LSAPC |

| Cabinet class according to ЕN 12469-2000, NSF/ANSI 49 | II |

| Description of the cabinet as per DIN 12980:2017-05 | Cabinet for cytotoxic substances |

| Class of the installed НЕРА-filters according to EN 1822-1 | Н14 |

| Average velocity of the inflow though the work opening, m/s | 0,47±0,03 |

| Average downflow velocity in the working chamber, m/s | 0,35+0,01 |

| Illuminance level in the working zone, lux, not less than | 2000 |

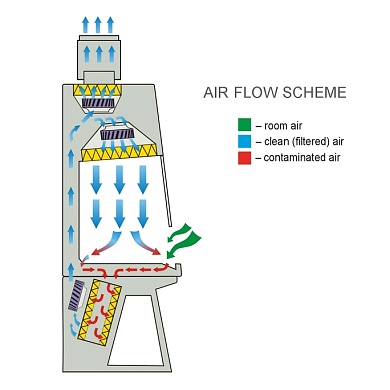

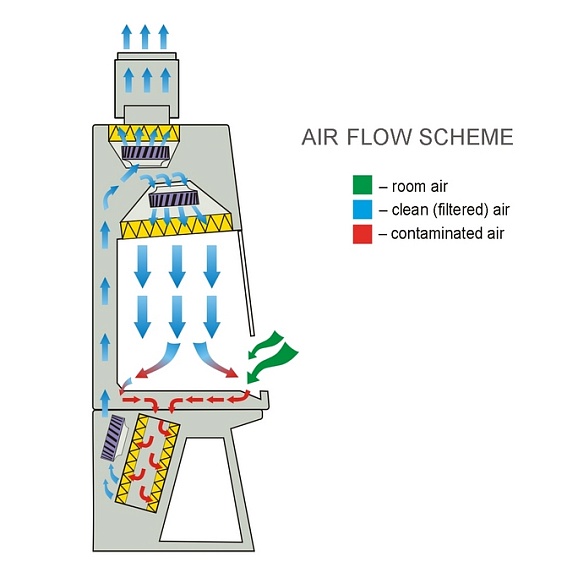

| Air recirculation rate in the cabinet, % | ≈70 |

Dimensional drawing

Air flow scheme

Standard Configuration

Work Chamber

- power driven sliding front sash made of laminated safety glass;

- side windows made of tempered glass: with tap ports on the right, solid on the left;

- slanted front surface of the cabinet;

- work chamber LED lighting;

- electric sockets in the work chamber (2pcs. on the left part of the rear wall);

- airflow laminarization screen made of polymer micromesh;

- air intake grille in the rear wall of the work chamber;

- removable tabletop (operating middle section and two side sections) made of stainless steel (AISI 304);

- work chamber tray made of stainless steel (AISI 304);

- removable armrest made of stainless steel (AISI 304).

Sash Lifting/Lowering

- the front aperture opening and closing is carried out by moving the front sash in the plane of the aperture;

- power drive;

- the sash is hanging on the two flat belts rigidly fixed to the glass;

- there is no counter-weight in the configuration.

UV unit

- pullout UV unit (when inoperative, is stored outside of the work chamber under the tabletop);

- metal grille protecting the UV lamp;

- dampers against any impact upon lowering the work opening screen.

Supply and Exhaust Air Filtration System

- the inner and exhaust airflows pass two-stage filtration ensured by:

- one supply HEPA filter H14 located above the work chamber;

- four parallel preliminary cylindrical HEPA filters H14 located under the tabletop;

- one exhaust HEPA filter H14 located in the upper ventilation chamber.

Control System Components

- microprocessor control system;

- touchscreen control panel;

- airflow sensors*;

- front sash and UV unit position sensors;

- belt tension sensors;

- individual fuse for power supply to the main functions of the cabinet (fan, lighting, UV lamp);

- individual fuse for electric sockets of the work chamber;

- removable power cord.

Additional Components

- caster wheels for cabinet relocation;

- screw supports for cabinet fixation at operating site.

HEPA Filter Integrity Testing Components

- outlets located in the right part of the rear wall for testing the supply and exhaust HEPA filters as well as preliminary cylindrical HEPA filters.