BMB-II-Laminar-S.-1,2 VIS-A-VIS Biological Safety Cabinet

Microbiological safety cabinet class II VIS-A-VIS is designed to work with lab animals.

The design of VIS-A-VIS cabinet allows two operators working opposite one another at the same time.

It provides product, operator and environment protection when working with agents of biosafety levels 1, 2 and 3.

MAIN FEATURES

It is equipped with a system of monitoring the operating modes; optical sensors of the front glasses, the UV-unit and the safety closure position; a control panel with LCD touch screen, where operation information of the cabinet is displayed. The audio-visible alarm system is activated upon failure of the safety conditions.

Downward laminar air flow prevents the materials cross contamination in the working zone. The animals’ hair catcher is installed under the table top.

A unique pull out UV-unit is included into the basic configuration.

The cabinet is designed for operation in standing or seating position.

Support stand for operators in standing position (height of the working surface is 1,008 mm) .

BMB-II-Laminar-S.-1,2 VIS-A-VIS Biological Safety Cabinet

Microbiological safety cabinet class II VIS-A-VIS is designed to work with lab animals.

The design of VIS-A-VIS cabinet allows two operators working opposite one another at the same time.

It provides product, operator and environment protection when working with agents of biosafety levels 1, 2 and 3.

MAIN FEATURES

It is equipped with a system of monitoring the operating modes; optical sensors of the front glasses, the UV-unit and the safety closure position; a control panel with LCD touch screen, where operation information of the cabinet is displayed. The audio-visible alarm system is activated upon failure of the safety conditions.

Downward laminar air flow prevents the materials cross contamination in the working zone. The animals’ hair catcher is installed under the table top.

A unique pull out UV-unit is included into the basic configuration.

The cabinet is designed for operation in standing or seating position.

Support stand for operators in standing position (height of the working surface is 1,008 mm) .

Main parameters and dimensions

Microbiological safety cabinet BMB-II-“Laminar-S.”-1,2

NEOTERIC VIS-À-VIS Class II

| Article | 2Е-В.004-12 |

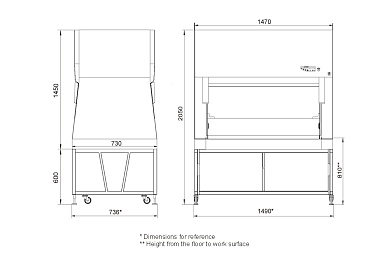

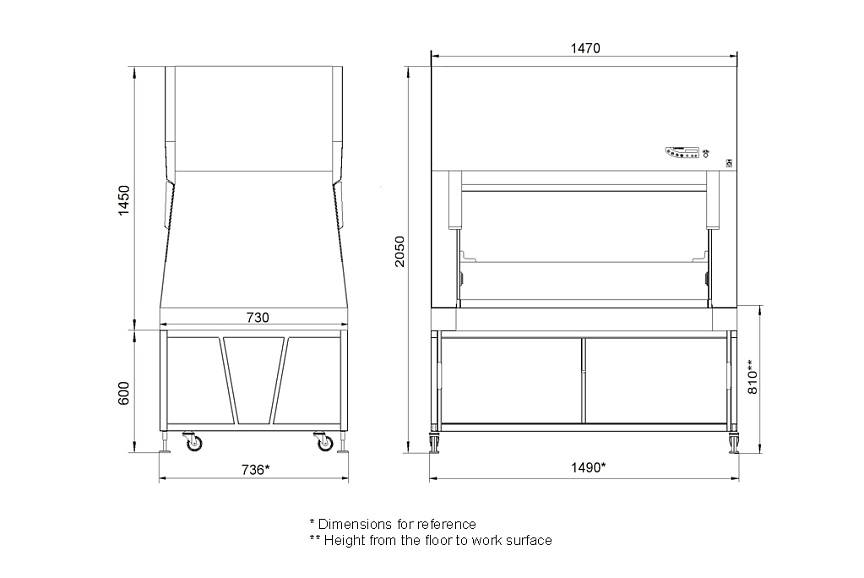

| Maximum dimensions of the cabinet /WхDхH/* (dimensions without stand are in parenthesis),mm | 1470х730х2050 (1450) |

| Maximum dimensions of the stand /WхDхH/*,mm | 1470х730х600 |

| Dimensions of the work chamber /WхDхH/, mm | 1110х700х670 |

| Dimensions of the work zone /WxD/, mm | 1110х475 |

| Area of the work zone, m2 | 0,53 |

| Dimensions of the work openings /WxH/, mm | 1110х195 |

| Dimensions of HEPA filters: | |

| Supply HEPA filter /WxDxH/, mm | 1130х530х78 |

| Exhaust HEPA filters /WxDxH/, mm | 480х530х78 |

| Power Supply: | |

| - voltage ~, V | 220-240 |

| - frequency, Hz | 50 |

| Maximum input power, W | 1620 |

| Maximum input power without built-in electric sockets, W | 620 |

| Maximum allowed load on the built-in electric sockets, W | 1000 |

| Power of the UV lamp, W | 30 |

| Power of LED lamp, W | 39 |

| Number of LED lamps | 2 |

| Maximum net weight of the cabinet assembled with stan, kg | 330 |

| Height from bottom to work surface, mm | 810 |

* dimensions do not account for outstanding supports

MAIN CHARACTERISTICS

| Installation work chamber air cleanliness class for suspended particle (aerosol) concentration as per ISO 14644-1:2015 | |

| - for particles of 0.5µm and more | 5 ISO |

| - for particles of 5.0µm and more | ISO М (20; ≥ 5 мкм);LSAPC |

| Class of the cabinet as per EN 12469-2000, NSF/ANSI 49 | II |

| Type of the cabinet as per NSF/ANSI 49 | А2 |

| Average downflow velocity in the work chamber | 0,35+0,01 mps |

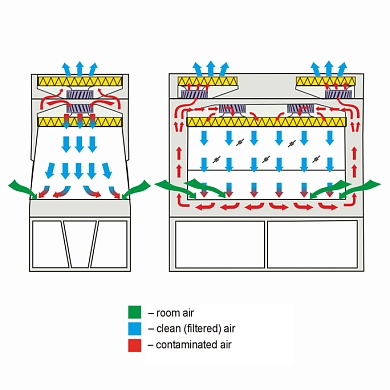

| Work chamber airflow type | unidirectional (laminar) downflow |

| Average velocity of the inflow though the working opening | 0,47±0,03 mps |

| Work opening airflow type | directed into the front grille of the tabletop, creating air curtain |

| Downflow | 690-710 m3/h |

| Outflow: | |

| - when both of the front openings are open | 665-755 m3/h |

| - when one front opening is open | 330-375 m3/h |

| Air recirculation | 50/50 % |

| HEPA filters | |

| 1) class as per EN 1822-1 | Н14 |

| 2) retention at MPPS | 99.995% |

| 3) minimum service life | 4* years |

| UV lighting | |

| - UVC radiant flux | 11.2 W |

| - lumen depreciation after 5000 hours of work | 12% |

| - service life | 8000 hours |

| Minimum illumination of the work zone (integral value determined along the whole area of the work zone) | 1500 lx |

| Maximum noise level at 1 m distance from the cabinet | 60** dB |

* provided the cabinet is operated in accordance with the requirements of the Manual.

** level of noise measured as per DIN EN ISO 11201 in free sound field over the sound-reflecting surface (noise level in real operating environment depends on the dimensions of the operating site as well as and on the total background noise and may vary by 3-4 dB(A))

Dimensional drawing

Air flow scheme

Standard Configuration

Work Chamber:

- two front openings for simultaneous work of two operators opposite one another;

- slanted front surfaces of the cabinet;

- hinged front sashes made of laminated safety glass; opening, closing and upholding is carried out by gas springs;

- dampers against front sash closing impact;

- work chamber LED lighting;

- four electric sockets in the work chamber (2 on right and to on the left side wall);

- airflow laminarization screen made of polymer micromesh;

- three-section tabletop made of mirror stainless steel (AISI 304) with air intake grille;

- work chamber tray made of stainless steel (AISI 304);

- two removable armrests made of stainless steel (AISI 304)

Pullout Units with Work Opening Screens and a UV Lamp:

- two pullout units with work opening screens one of which is featured with a UV lamp

- pullout units are located under the work chamber;

- dampers against any impact upon lowering the work opening screen.

Supply and Exhaust Air Filtration System:

- two fans ensuring air supply into the cabinet;

- two exhaust plenums each one equipped with a fan ensuring air exhaust out of the cabinet;

- supply air coming into the work chamber is cleaned by supply HEPA filter H14;

- exhaust air coming out of the cabinet is cleaned by exhaust HEPA filters H14.

Control System Components

- microprocessor control system;

- pushbutton control panel with LCD screen;

- electromagnetic reader and electromagnetic access keys;

- airflow sensors*;

- front sash and UV unit position sensors;

- individual fuse for power supply to the main functions of the cabinet (fan, lighting, UV lamp);

- individual fuse for electric sockets of the work chamber;

- built-in power cord with holder

Stand:

- frame stand with footrest;

- caster wheels for cabinet relocation;

- screw supports for cabinet fixation at operating site.

Additional Components:

- mounting wrench kit;

- special foam bricks for cabinet mounting.

Testing and Adjusting Components:

- built-in outlets for sampling the air upstream of HEPA filters for their integrity testing.