Dynamic pass box with HEPA-filter H14

The pass box is designed for transferring materials between rooms of different cleanliness class* maintaining the air cleanliness class and pressure parameters there as well as preventing any direct contact of the air of the rooms and eliminating any risk of cross-contamination.

*As per ISO 14644-1 Cleanrooms and associated controlled environments. Part 1. Classification of air cleanliness.

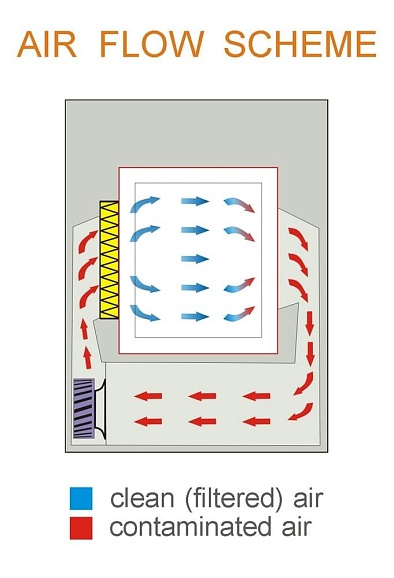

The operation of the pass box is based on 100% RECIRCULATION of the air inside its body.

CONVENIENCE AT EXPLOITATION

“Call-out” function calls for an operator from the opposite side using the sound signal, which is important when the pass box is installed between the rooms isolated from each other.

UV unit’s operating parameters and clean air purge mode parameters can be set independently for each side of the pass box allowing the materials to be disinfected and purged with clean air different amounts of time when transferred from the hazardous zone to the clean one and vice versa.

Adjustable parameters of UV disinfection and clean air purge: time interval of the UV-irradiation; time interval of the clean air purge; automatic enabling of the UV- irradiation/ the clean air purge when materials are transferred.

Audible-visible alarm automatically warns the user: when the UV-irradiation/ clean air purge cycle is completed and the materials and items may be removed (at the receiving side); when the person is called from the other side.

“Cleaning” mode is designed for sanitary disinfection of the work chamber of the pass-box without enabling of the audible and visible alarm.

The touchscreen control panel allows work in gloves and wet disinfection.

SECURITY

- In case of power failure, doors of the pass box are staying locked.

- Automatic activation of audible and visible alarm if the door of pass box is open for more than one minute.

- Pass box doors are automatically blocked during UV-irradiation/clean air purge.

- Protection from the simultaneous opening of the pass box doors is executed by automatic locking of the door on the side of passing/receiving person when the door is opened on the opposite side by receiving/passing person.

Dynamic pass box with HEPA-filter H14

The pass box is designed for transferring materials between rooms of different cleanliness class* maintaining the air cleanliness class and pressure parameters there as well as preventing any direct contact of the air of the rooms and eliminating any risk of cross-contamination.

*As per ISO 14644-1 Cleanrooms and associated controlled environments. Part 1. Classification of air cleanliness.

The operation of the pass box is based on 100% RECIRCULATION of the air inside its body.

CONVENIENCE AT EXPLOITATION

“Call-out” function calls for an operator from the opposite side using the sound signal, which is important when the pass box is installed between the rooms isolated from each other.

UV unit’s operating parameters and clean air purge mode parameters can be set independently for each side of the pass box allowing the materials to be disinfected and purged with clean air different amounts of time when transferred from the hazardous zone to the clean one and vice versa.

Adjustable parameters of UV disinfection and clean air purge: time interval of the UV-irradiation; time interval of the clean air purge; automatic enabling of the UV- irradiation/ the clean air purge when materials are transferred.

Audible-visible alarm automatically warns the user: when the UV-irradiation/ clean air purge cycle is completed and the materials and items may be removed (at the receiving side); when the person is called from the other side.

“Cleaning” mode is designed for sanitary disinfection of the work chamber of the pass-box without enabling of the audible and visible alarm.

The touchscreen control panel allows work in gloves and wet disinfection.

SECURITY

- In case of power failure, doors of the pass box are staying locked.

- Automatic activation of audible and visible alarm if the door of pass box is open for more than one minute.

- Pass box doors are automatically blocked during UV-irradiation/clean air purge.

- Protection from the simultaneous opening of the pass box doors is executed by automatic locking of the door on the side of passing/receiving person when the door is opened on the opposite side by receiving/passing person.

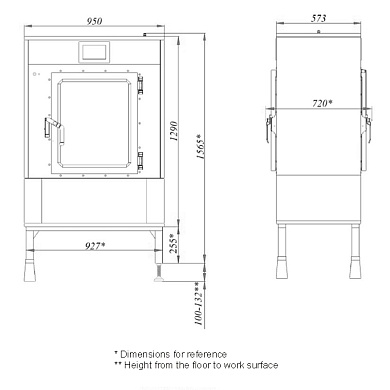

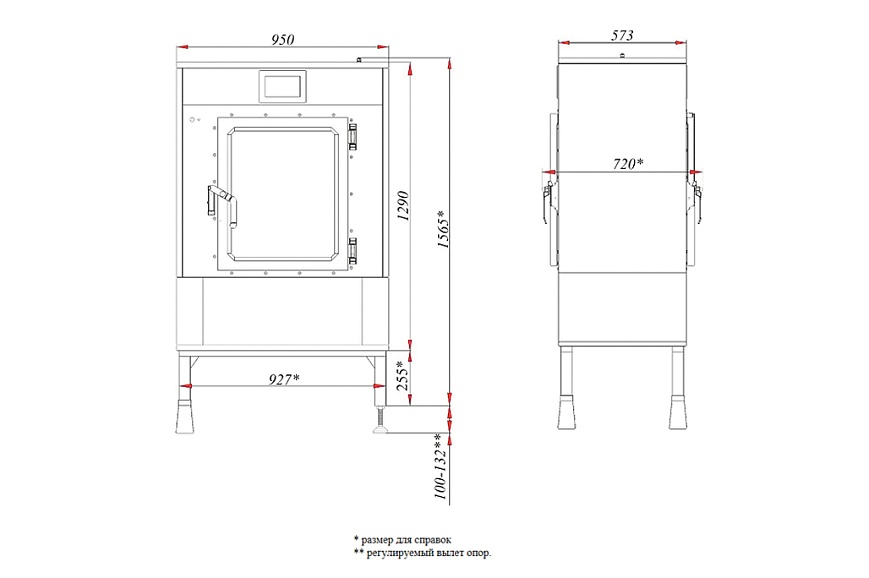

Main parameters and dimensions

TECHNICAL AND EXPLOITATIONAL CHARACTERISTICS

| Article | 2E-P.115-99 |

| Dimensions of the pass box /WхDхH/, mm, not more than | 950х720х1290 |

| Dimensions of the pass box work chamber /WxDxH/, mm, not more than | 555х585х655 |

| Dimensions of the work opening of the pass box /WхH/, mm. | 500x600 |

| Class of HEPA filter as per EN 1822-1 | H14 |

| Minimum time of fan operation, sec | 10 |

| Maximum time of fan operation (to be set), hours:minutes:seconds | 23:59:59 |

| Time of Class 5 cleanliness recovery in the work chamber not more than, min | 1 |

| Power of clean air supplied into the work chamber, m3/h | ≈200 |

| The rate of air exchange in the work chamber at the nominal performance of the product for "clean" air, not less than 1/hour | ≈1000 |

| Pass box UV irradiations parameters: | |

| – power of the UV-lamp, W | 8 |

| – UV-C radiant power, W | 2,1 |

| – reduction light radiant in efficiency in 5,000 hours of operation, % | 20 |

| Parameters of the pass box power consumption: | |

| -type of the power network | L+ N +PE |

| -frequency, Hz | 50 |

| -nominal voltage, V | 220±10% |

| Maximum input power, W | 130 |

| Maximum weight of the pass box, kg | 150 |

Dimensional drawing

Air flow scheme

Standard Configuration

STANDARD CONFIGURATION of the Pass Box

- WORK CHAMBER is made of stainless steel AISI 304.

- TOUCH SCREEN CONTROL PANELS are located on both sides of the pass box and carry out pass box control.

- LEAK-TIGHT OUTER CASING made of powder-coated stainless steel AISI 304.

- FACE FRAMES made of metal ensure reliable and aesthetic sealing of the junction with the room wall.

- DOORS featured with electromechanical interlocks and windows made of laminated safety glass.

- FRAME STAND with screw supports simplifies the installation allowing height adjustment.

- Face DUST GUARDS for covering the screw supports.

- HEPA filter H14.

- TWO BUILT-IN OUTLETS: outlet for HEPA filter integrity testing; outlet for leak-tightness testing of the casing and the work chamber.

- TURBOLISER ensures uniform distribution of airflow inside the pass box allowing effective air purification.

- Two UV lamps protected from mechanical damage are designed for disinfection of transferred materials. UV lamps are able to work with turn on fan, as well as separately from it.

INSTALLATION

- Pass box may be integrated into the partition made of almost any material.

- When installing the pass box without the frame stand into the load-bearing walls (made of bricks, concrete, etc.), the wall thickness should not be more than 500 mm.

- When installing the pass box into the light and thin walls (such as drywall or walls made of metal) the wall thickness should not be more than 380 mm.

- In that case frame stand should not be removed to ensure steadiness of the pass box during the entire period of operation.

- Installation place of the pass box should be equipped with power supply.